The resulting figure is the rate that will be applied to the allocation base throughout the accounting period to assign overhead costs to products or services. It is important to regularly review and Sales Forecasting update this rate to reflect changes in costs or operating conditions. For instance, if a company experiences a significant change in production technology, it may need to revise its overhead rate to account for the shift in cost structure. Calculating the predetermined overhead rate plays a pivotal role in cost accounting, providing a basis for allocating manufacturing overhead costs to products.

Estimated Total Manufacturing Overhead Costs

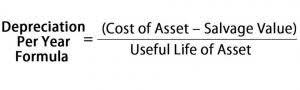

This rate is calculated by dividing the estimated manufacturing overhead cost for a period by the estimated total units in the allocation base for that same period. A predetermined overhead rate is an estimated charge per unit of activity that is predetermined overhead rate used to assign overhead costs to products or job orders. This rate is established before a period begins, based on projected figures, rather than actual costs incurred. It is a proactive approach, allowing businesses to streamline the cost allocation process and manage indirect expenses that are not directly traceable to a single product or service. You can calculate this rate by dividing the estimated manufacturing overhead costs for the period by the estimated number of units within the allocation base.

Machine Hours Example

- Hence, the fish-selling businesses need to monitor the seasonal variations and adjust the cost pattern of the products.

- After the period for a predetermined overhead rate ends, the business is left with a credit on the ledger or a debit to pay, which will ultimately have an impact on quarterly and annual profit figures.

- Factors such as inflation, changes in production technology, or shifts in the mix of products or services offered can all affect the accuracy of the overhead rate.

- The overhead rate is calculated by dividing total overhead costs by an appropriate allocation measure such as direct labor hours.

- At the end of the accounting period, the actual indirect cost is obtained and compared with the absorbed indirect.

- For instance, if the activity base is machine hours, you calculate predetermined overhead rate by dividing the overhead costs by the estimated number of machine hours.

If the actual overhead at the end of the accounting period is 1,575 the overhead bookkeeping is said to be under applied by 125 (1,450 – 1,575). If the actual overhead at the end of the accounting period is 1,575 the overhead is said to be over applied by 25 (1,600 – 1,575). The overhead will be allocated to the product units at the rate of 10.00 for each machine hour used.

B. Select Allocation Base

These two factors would definitely make up part of the cost of producing each gadget. Thus the organization gets a clear idea of the expenses allocated and the expected profits during the year. The concept of predetermined overhead is based on the assumption that the overheads will remain constant, and the production value is dependent on it. We can calculate predetermined overhead for material using units to be allocated. For example, we can use labor hours worked, and for calculating overhead for the store department, we can use the quantity of material to be used. Many accountants always ask about specific time which we need to do this, at what point in time is the predetermined overhead rate calculated.

- Predetermined overhead cost rates are essential for timely cost allocation, budgeting, and financial reporting.

- When actual overhead costs are higher than originally estimated, they are said to be under-absorbed.

- It’s important to note that if the business uses the ABC system, the individual activity is absorbed on a specific basis.

- The total manufacturing overhead cost will be variable overhead, and fixed overhead, which is the sum of 145,000 + 420,000 equals 565,000 total manufacturing overhead.

- Carefully tracking overhead expenses is key for small businesses to optimize costs.

- If you’d like to learn more about calculating rates, check out our in-depth interview with Madison Boehm.

So, for every machine hour you clock while manufacturing your furniture during the year, you would apply $25 of your estimated overhead costs to that product. Accurately calculating overhead rates is important for determining the full cost of a product and appropriately pricing goods and services. That amount is added to the cost of the job, and the amount in the manufacturing overhead account is reduced by the same amount.